Renowned Global Ophthalmologist Professor Gerd U. Auffarth Explores the Innovative Features of Cross-linked Polyolefin IOLs

The evolution of intraocular lens (IOL) materials has remained relatively stagnant for over 30 years. Recently, however, the emergence of a novel biomaterial — cross-linked polyolefin (xPIB) — has broken this deadlock. Independently developed by Chinese innovation-driven company Xi’an Eyedeal Medical Technology Co., Ltd., xPIB has been introduced for the first time in IOL development. The pioneering launch of the Eyedeal™ next-generation cross-linked polyolefin IOL has garnered significant attention in both academic and industrial circles. But what makes this new material so special?

Recently, Professor Gerd U. Auffarth — Director of the globally renowned David J. Apple Laboratory and one of the top experts in IOL research — was interviewed by Cake Magazine, a leading international ophthalmology publication. In the interview, Professor Auffarth explored the wide-ranging potential of xPIB, its significance in ushering in a new era for IOLs, and its role in driving technological progress and transformation within the ophthalmic industry.

The following content is excerpted from the article “Cross-linked Polyisobutylene: Is This the Future of IOL Materials?”

In the interview, Professor Auffarth provided an in-depth explanation of the research background, material advantages, clinical data, and regulatory progress of xPIB. He expressed strong confidence in the material, stating that this new development is poised to reshape the landscape of the IOL industry and inject new momentum into global medical innovation and advancement.

Beyond Acrylic

Although xPIB is hailed as a breakthrough in IOL material technology, the medical field is not entirely unfamiliar with it. A related polyisobutylene material, SIBS, has already achieved successful clinical use in fields such as cardiology and ophthalmology. “This class of materials (SIBS) has been used as vascular stents in cardiology for 15 to 20 years,” said Professor Auffarth. “They are highly suitable for implantation with no adverse material-related reactions.”

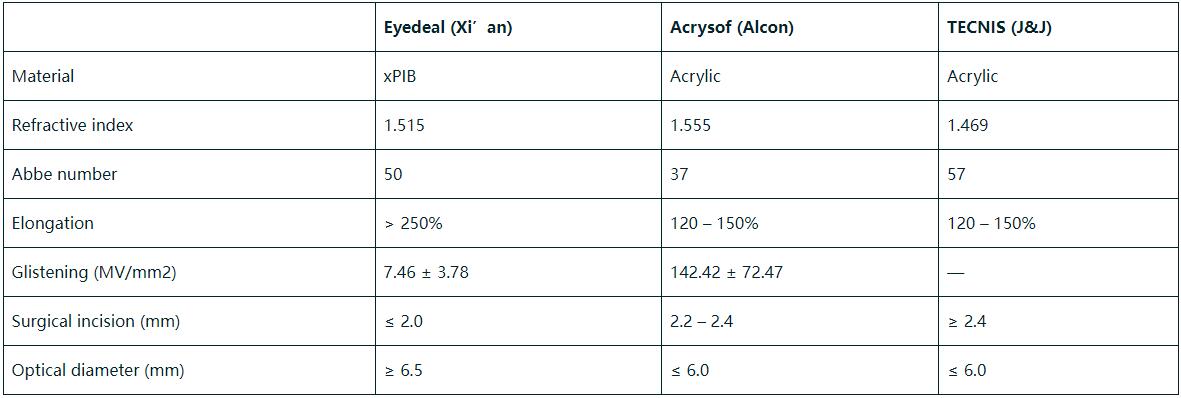

Unlike traditional acrylic materials, the Eyedeal IOL made from xPIB exhibits several outstanding optical and physical properties. When comparing IOL materials, refractive index and Abbe number are crucial factors. The refractive index indicates how much light is bent, while the Abbe number measures dispersion. Generally, higher refractive indices come with lower Abbe values (indicating more dispersion). Remarkably, xPIB offers both a high refractive index (1.515) and a high Abbe number (50), making it one of the most desirable materials for IOLs and a standout advantage of xPIB.

Another key benefit is its exceptional elasticity. xPIB can be stretched over 250% without damage, making it easier to fold and implant. “This material enables the creation of larger optical zones that can still be inserted through micro-incisions,” Auffarth noted — paving the way for IOLs with larger optical surfaces.

This data was drawn from Professor Auffarth’s research on the Eyedeal IOL and his presentation at the 35th Annual Meeting of the Asia-Pacific Association of Cataract and Refractive Surgeons (APACRS).

To IOL experts, the advantages of xPIB IOLs in enabling new optical designs and accelerating postoperative recovery are already evident — but the potential of xPIB goes far beyond that.

Another compelling advantage of xPIB is its “zero glistenings” performance. Traditional IOLs are prone to microvacuoles (glistenings) that form once implanted, leading to increased light scatter and reduced visual quality. Following an in-depth evaluation of the new-generation Eyedeal™ xPIB IOL, Professor Auffarth and his team found it exhibited extremely low glistening density — ensuring long-term clarity and stability after implantation.

In his presentation at the 35th APACRS, Professor Auffarth compared the Eyedeal IOL with currently available IOLs and concluded that it outperformed others in multiple categories, including Abbe number, elasticity, refractive index, glistening resistance, minimum incision size, and optical zone diameter.

The future looks bright

Currently, the Eyedeal IOL is undergoing registration and multi-center clinical trials in countries like Germany and Lithuania. After the trials are completed and CE certification is obtained, it is expected to be launched in Europe the following year. The clinical trial in China has already been completed and “approval is expected soon,” Professor Auffarth added.

xPIB’s numerous advantages make it suitable not only for standard IOLs but also for premium IOL designs. “Any type of optical design — from basic to advanced technologies like trifocal lenses — can be realized with this material,” Auffarth explained. The unique performance attributes of xPIB open new possibilities for optical designs that were previously unachievable with existing IOL materials. “The industry is watching closely,” he noted. “There’s a great deal of interest in this new material and its transformative potential.”

The field of ophthalmology continues to evolve, and the introduction of the xPIB IOL represents a major technological leap forward. With its exceptional properties and validated clinical performance, xPIB stands out as the ideal material for next-generation IOLs. As research progresses and market approvals are secured, xPIB will significantly broaden the design potential of new IOLs and improve postoperative outcomes and visual experiences for cataract patients around the world.

As a revolutionary force in IOL materials, xPIB — with its remarkable properties and vast potential — is ushering in a new era. With the joint efforts of all sectors, xPIB is set to continue creating breakthroughs and bringing clearer vision and brighter lives to more people worldwide.